www.automation-mag.com

15

'22

Written on Modified on

Nabtesco News

Neco®HT A new standard for heavy-duty applications

The user-friendly gears of Nabtesco’s Neco® series have made robot technology accessible in conventional machine and plant engineering.

Modular high-torque gears for heavy loads

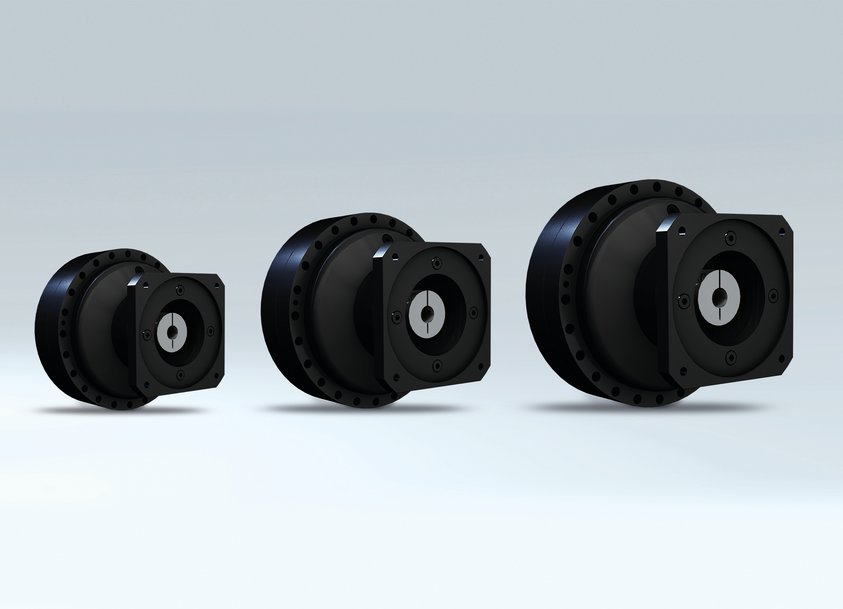

Now the cycloidal gear specialist is expanding the successful series to include models that are dimensioned for heavy-duty applications. The new high-torque gears with the name Neco®HT feature a modular gear design and are setting standards with respect to precision, robustness and user convenience.

The new high-torque gears of the Neco®HT series are designed for torque ratings from 3,800 to 7,000 Nm and guarantee high-precision positioning in scenarios involving large loads and high forces. They feature a clean and closed design, achieve high precision with a hysteresis loss of only 0.5 arc.min and are extremely robust, due to double-bearing eccentric shafts and a bearing-mounted drive shaft. Comprehensive corrosion protection – both the gear output shaft and the faces of the shaft seals are corrosion resistant – minimises or even eliminates the risk of failures due to corrosion. A redundant seal system on the drive side provides additional protection in this regard.

Economical series production of large precision gears

A unique aspect of the new series is the high level of modularity and standardisation in the area of large precision gears. The combination of standardised elements easily allows for numerous defined interfaces for use with a broad spectrum of drives. This guarantees not only faster assembly and maximum flexibility with respect to the motor connection, but also economical series production and high availability with shorter delivery times.

High-torque gears with a cycloidal design

Heavy loads are generally moved by means of hydraulic systems or large planetary gears. However, cycloidal gears are clearly superior in most cases. Their special design principle achieves very high reduction ratios with only two to three gear stages, which guarantees precise positioning in a very compact design. In cycloidal gears, power transmission is achieved by cams and rollers. That assures absolutely precise positioning, no backlash combined with high dynamics, and enormous resistance to shock loads (up to 500 % of the rated torque) throughout the entire lifetime.

Specialists for high loads

The Neco®HT series from Nabtesco provides customer-friendly plug & play gears for high torques, and therefore closes the gap between robotics and industrial gears.

Whether in machine and plant engineering, sheet and steel metalworking or aircraft construction: In every type of application where heavy loads have to be positioned with pinpoint precision, the new heavy-duty gears are an efficient alternative to conventional technologies. Neco®HT high-torque gears are currently in prototype status. Three sizes are currently planned: Neco®HT-380 (3,800 Nm), Neco®HT-500 (5,000 Nm) and Neco®HT-700 (7,000 Nm).

www.nabtesco.com